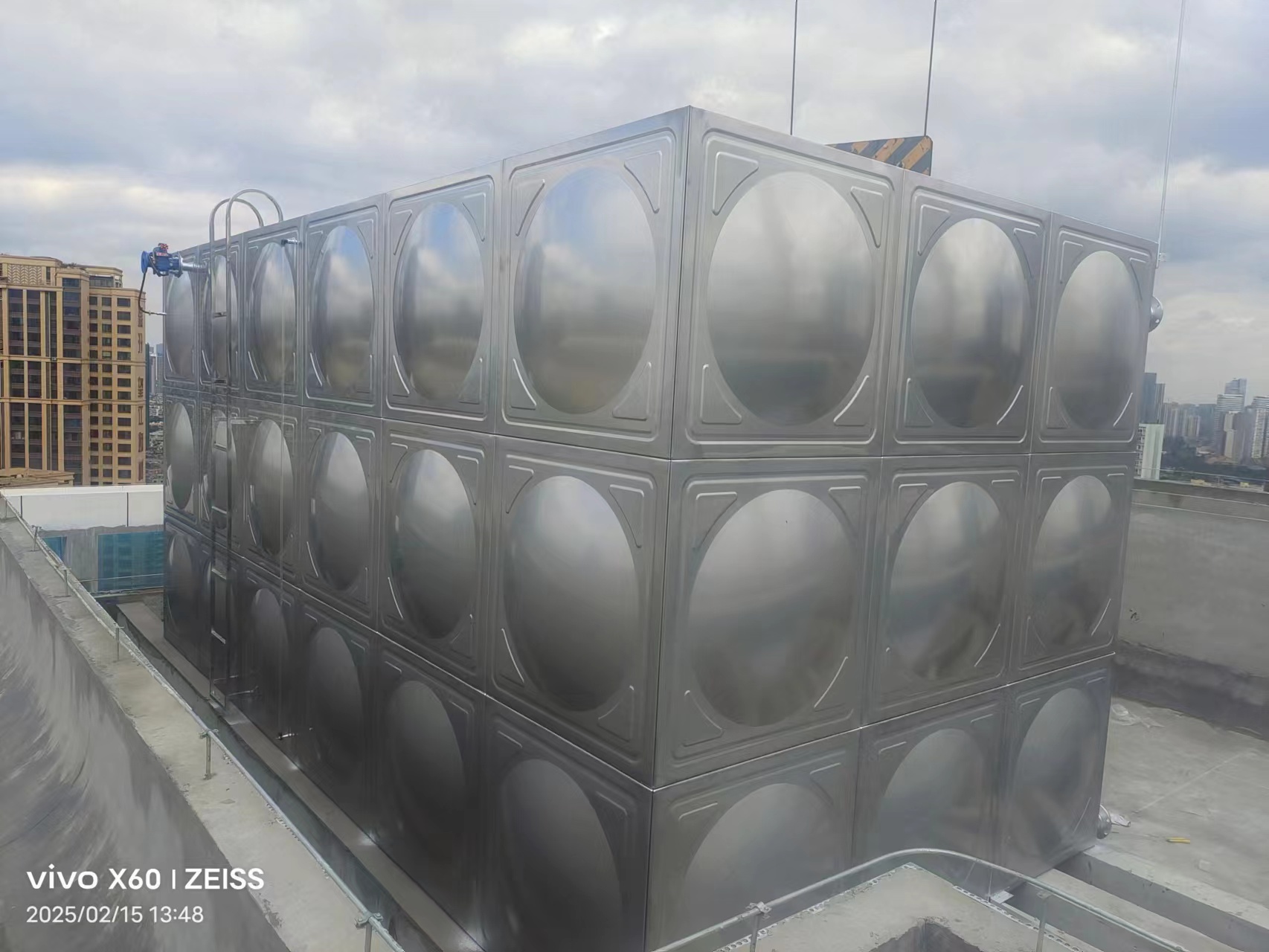

不锈钢水箱焊缝检测:工业内窥镜/X光探伤操作手册

stainless steel water tank welds are critical components in various industrial and municipal applications, ensuring the safe storage and transportation of water and other liquids. To guarantee the reliability and longevity of these systems, it is essential to perform thorough weld inspections. Two widely used methods for weld inspections are industrial endoscopes and X-ray radiography. This article will provide a detailed guide on how to perform these inspections and maintain the integrity of stainless steel water tanks.

1. 工业内窥镜检测

Industrial endoscopes, also known as borescopes, are advanced imaging devices used to inspect welds in hard-to-reach areas. These devices are particularly useful for stainless steel water tanks, where welds may be located in confined spaces or inaccessible locations.

操作步骤:

设备准备 确保工业内窥镜处于正常工作状态,包括检查电池电量、镜头清洁度以及设备的灵活性。选择适合检测环境的内窥镜类型,例如.AddParameter("清水")- if the weld is in a dry environment, a standard industrial endoscope may suffice. For wet or corrosive environments, consider using an waterproof model.

表面清理 在进行内窥镜检测之前,需要彻底清理焊缝周围的氧化皮、焊渣和其他杂质,以确保清晰的视野。可以使用砂纸、钢丝刷或化学清洁剂进行清洁。

插入镜头 将内窥镜的镜头缓慢插入焊缝部位,注意避免损坏镜头或刮伤焊缝表面。调整镜头的角度和位置,以获得最佳的观察效果。

观察与记录 通过内窥镜的显示屏,仔细观察焊缝的外观质量,包括焊纹、气孔、裂纹、未融合和咬边等缺陷。记录发现的缺陷类型、位置和严重程度,为后续的修复和评估提供依据。

设备保存 检查完成后,及时清理镜头上的残留物,并将设备存放在干燥、防尘的环境中,以延长设备的使用寿命。

2. X光探伤检测

X射线 radiography 是一种无损检测方法,通过X射线穿透焊缝,生成胶片或数字图像,从而发现焊缝内部的缺陷。这种方法适用于检测焊缝的深度和宽度,是不锈钢水箱焊缝检测的重要手段。

操作步骤:

准备工作 确保X射线设备正常运行,并根据焊缝的厚度和材质选择合适的X射线管和胶片。穿戴适当的防护装备,如铅围裙和防护手套,以确保操作人员的安全。

安装胶片 将胶片放置在与焊缝平行的位置,并确保胶片与焊缝之间的距离符合设备说明书的要求。使用铅板或其他防护材料覆盖不必要的区域,以防止X射线的散射。

调节参数 根据焊缝的厚度和材质,调整X射线的曝光时间、电流和电压,以获得清晰的图像。参考设备说明书或咨询专业人员,确保参数设置正确。

进行曝光 在确保操作人员和周围人员安全的情况下,启动X射线设备,完成曝光过程。曝光时间应根据焊缝的具体情况调整,以确保胶片能够清晰显示焊缝的结构。

显影与处理 曝光完成后,将胶片放入显影液、定影液和清洗液中进行处理,以获得清晰的X光照片。数字X射线设备可以直接在屏幕上显示图像,无需胶片处理。

分析与记录 通过X光照片,仔细分析焊缝内部的缺陷,如气孔、夹渣、裂纹和未融合等。记录发现的缺陷类型、位置和严重程度,并为后续的修复提供依据。

设备维护 检查完成后,清理设备表面的残留物,并将设备存放在干燥、防尘的环境中。定期检查X射线管和其他关键部件的状态,确保设备的长期稳定运行。

3. 不锈钢水箱焊缝检测的重要性

Weld inspections are crucial for ensuring the safety and reliability of stainless steel water tanks. Defects in welds can lead to leaks, corrosion, and even structural failure, which can result in significant losses and risks. By performing regular inspections using industrial endoscopes and X-ray radiography, we can identify and address potential issues early, ensuring the longevity and performance of the water tanks.

4. 结语

Performing weld inspections on stainless steel water tanks is a critical step in ensuring their safety and reliability. By utilizing industrial endoscopes and X-ray radiography, we can effectively detect and address weld defects, preventing potential failures and extending the service life of the tanks. Regular maintenance and inspections should be carried out by qualified professionals to ensure the continued safe operation of these systems.

成都源塔供水设备有限公司 specializes in the production and installation of high-quality stainless steel water tanks, and we offer professional weld inspection services to ensure the reliability of our products. If you have any questions or need assistance with your stainless steel water tank projects, please feel free to contact us.

服务热线:

服务热线: